ASTORE

Tilted carriage 17°

Main module with 1 clamp and 2 log turners + secondary modules with 1 clamp and 2 log turners for each module.

Quick and safe module displacement system that allows the operator to position the clamps according to the length of the logs to be sawed.

The log clamping and the modules positioning is done by the operator from the control cabin by means of a selector that acts on hydraulic locking pliers through a thick steel rope.

The distance between the modules is always displayed on the electronic device.

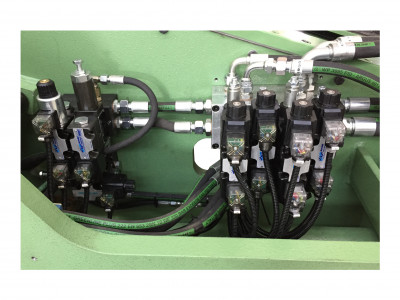

Hydraulic log clamping with 3 closing pressures

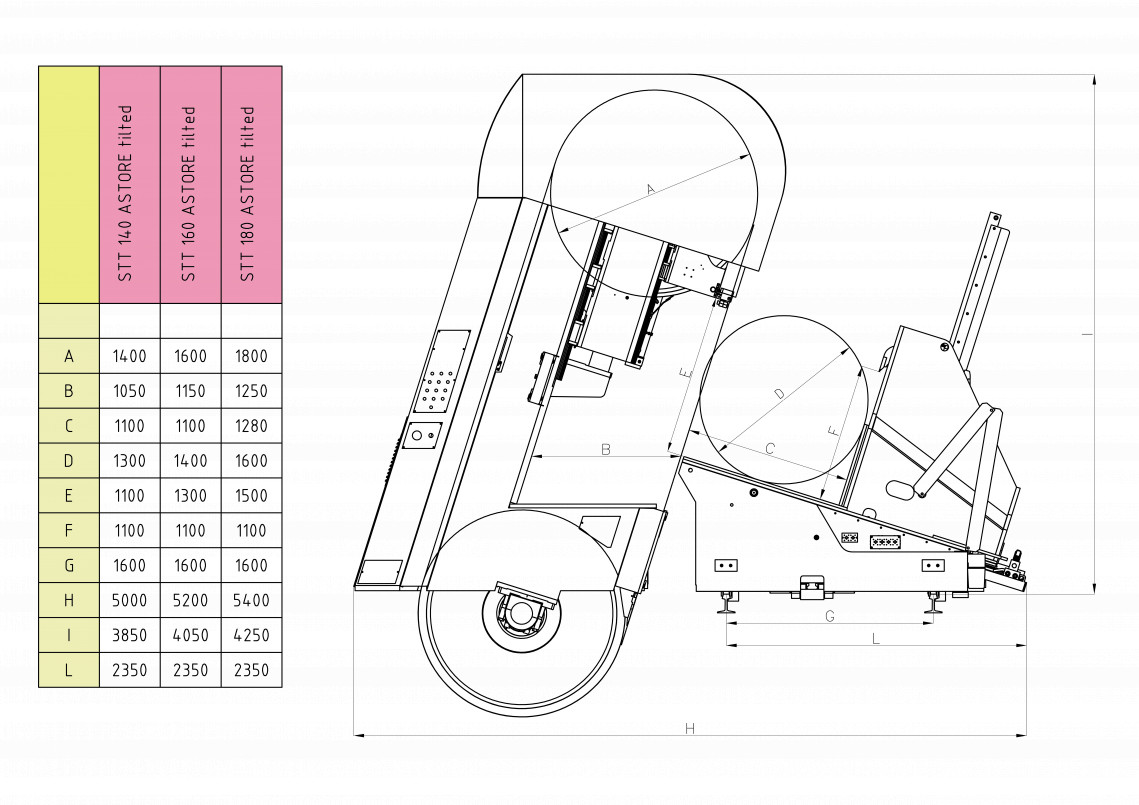

Opening clamp-blade 1300 mm

Hooks opening 1100 mm

Moving hooks protrusion 200 mm

Hydraulic log turners – 90° arm tilting – 1 ton each arm -chains rotation with hydraulic motor

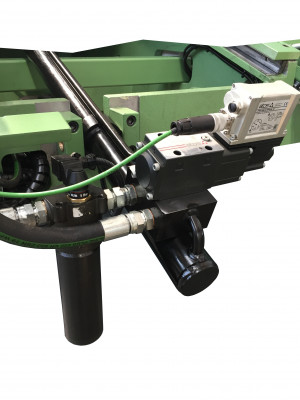

Clamp transversal movement with hydraulic cylinder driven by servovalve (1 in each single clamp)

Electronic thicknesses device with working programs Touch screen

Automatic lubrication

Carriage hydrostatic feed with steel cable drive

Hydraulic arm on each clamp to eject the last plank

UPON REQUEST:

Hydraulic slab turners

Hook suspension grippers

Hydraulic rope tensioner

Automatic speed control according to blade side-slip

Automatic log centering by means of scanner/laser system, with working programs, optimization and cubage

Electric longitudinal feed